|

-

Industry

Screw machining

Our machining centre is programmed using Mastercam cad software, and we can program and machine Small to Medium jobs in our sisters companies and offers screw machining for customers who need high-volume manufacturing of turned components. We specialize in the automated production of small parts, running 15,000 to 20,000 parts at one time.

Our highly trained staff and state-of-the-art equipment will provide precise, close tolerance machining of complex features on small components, first part to last. Its EOEC for your screw machining job!

Plate rolling

A Steel Plate Rolling Services Provider

The EOEC Holding company provides steel plate rolling services and alloy plate rolling services. Our certifed matal forming process can roll different types of metal stock from 3/8 inches to 11 inches thick. We provide hot rolling and cold rolling services to fabricate steel plate into a conical or round shapes,pressure vessels and other components. We manufacture rolled and welded cylinders and cones for our industrial customers. Our facilities include large plate rolling equipment, heavy steel plate rolling machines, roll bending machines and press brake forming machines.

The EOEC Company, also known as the EOEC Boiler & Engineering Company, specializes in steel and alloy plate rolling. We are an engineering, manufacturing and consulting firm specializing in heavy steel plate rolling, heavy steel plate bending and heavy steel plate fabricating services. Our experience in metal fabrication and steel solutions for heavy industry is invaluable. We roll PVQ quality carbon steel plate, 300 and 400 series stainless steel carbon alloys, nickel alloys, AR, and HSLA. We can roll and form thick or wide steel plate and provide welding, heat treating and engineering and metallurgical services

To talk to us about our steel and alloy plate rolling capabilities and services, call us or email info@EOEC.ir.

We can roll, bend, fabricate and process the following types of materials; PVQ Quality Carbon Steel Plate, 300 and 400 Series Stainless Steel, Aluminum, 4140, 4340 and 4150 Steel Plate, High Nickel Alloys, Copper, Abrasion Resistant Steel Plate and 11-14% Hadfield Manganese.

We specialize in plate rolling up to 4.5″ thick and in lengths up to 12′-8″. Contact The EOEC Company if your business requires heavy steel fabricating, forming and rolling, custom plate welding or custom plate rolling. Our custom plate rolling facilities are located in Cleveland, Ohio.

Our heavy plate rolling equipment and machines are operated by experienced craftsman that take pride in their plate rolling abilities. We also offer steel sourcing, pressure vessel and boiler construction and custom steel welding.

To get pricing on steel and alloy plate rolling services, to submit a design or CAD drawing, request a quote or submit an RFQ, ask a sales engineer a question, discuss your current project, place a fabrication order or to schedule a tour of our facilities, please call or email info@eoec.ir.

EOEC Plate Rolling Services has large plate rolling capacity in Iran with machines capable .

We strive to provide our customers with the highest quality plate rolling available. We can roll steel plate for pressure .

CNC machining

Long gone are the days of working in a gritty manufacturing plant - CNC Machining combines industrial arts with technical programming in clean environments. CNC Machinists produce a wide range of manufactured goods and work with a full line of raw materials - plastics, wood, metal and more. This skilled trades career calls for sophisticated programming skills to bring products from concept design to reality: from a piece of titanium, for example, to an artificial hip; from a piece of steel for gears for cars, trucks and airplanes; from a piece of wood to components for new home construction.

Balls

Machining Technologies has built a reputation as one of the world leading precision ball manufacturers. Through exclusive equipment design and on-site manufacturing processes, coupled with the fact that we do all of our own die making and tooling, we are able to give our valued customers an incredible edge on delivery time and price.

Quality is a commitment and a way of life at Machining Technologies. Our goal is to meet and/or exceed all customer order requirements and specifications.

We take particular pride in making our knowledgeable staffs available to you. These courteous and experienced people are ready to answer your questions and help make your ordering experience with Machining Technologies a very pleasant experience

We are ready to meet all your ball needs with virtually any materials, sizes and tolerance grades.Municipal Pumps

EOEC Municipal Pumps & Systems provide the flow power for clean water applications worldwide. This pump line includes Horizontal Split Case (HSC), Two-Stage DMD, End Suction, Vertical In-Line, Vertical Turbine and Axial and Mixed Flow models, as well as EOEC’s efficient .

EOEC technology helps transform even wastewater into a valuable resource. Reliable workhorses when it comes to accommodating the ebb and flow of major municipal sewage and storm water systems. Within the treatment plant where throughput is critical, our pumps are up to the task.

When Mother Nature assaults, Axial and Mixed Flow Pumps are ready to defend. Flood waters that threaten life and property stand little chance against the power, durability and reliability built into these behemoths. Engineered to move large volumes of water continuously and at high flow rates.

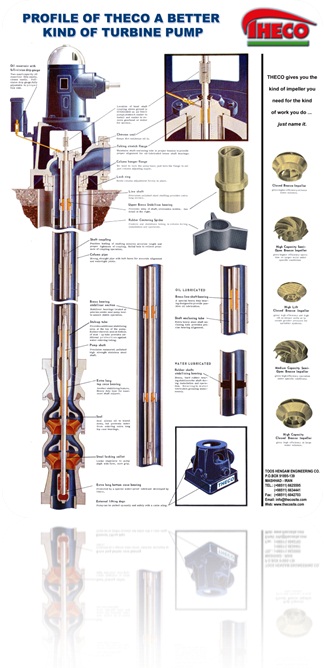

Pump

More commonly know as THECO(EOEC sister company) Pump is a large manufacturer of Mixed Flow & Centrifugal pumps in Iran. Since 1964, THECO has been building Mixed Flow pumps, initially for the market in Iran, and over the years has expanded into the international market. With annual sales in excess of $100 million USD producing over 10,000 tons of pumps a year, THECO Pump offers high quality, robust pumps at very competitive prices. A registered ISO9001 fabricator, THECO ensures that every unit that is shipped has been built in strict compliance with the ISO9001 established procedures.

EOEC provides a full line of slurry, submersible, dredging, sewage, chemical, petroleum and clear water pumps ranging from 5 to 900,000 cu. ft. per hour capacities. In 2006 THECO Pump moved into a modern environmentally friendly facility on 70 acres of land. In these plants, THECO forges its own pumps, builds its own motors, and produces all of the replacement parts required for prolonged service.

EOEC also has its own research institute, continually developing new designs using CAD and computer modeling to meet its customers‘ requirements. Pumps are made out of a variety of materials including but not limited to gray cast iron, nodular cast iron, nickel cast iron, steel casting, stainless steel casting, hi chromium casting, Ni-hard, Cr-Mo alloy, as well as natural rubber.

EOEC provides industrial equipment for customers around the world (see www.eoec.ir ) and is ready to assist customers in meeting their particular requirements.